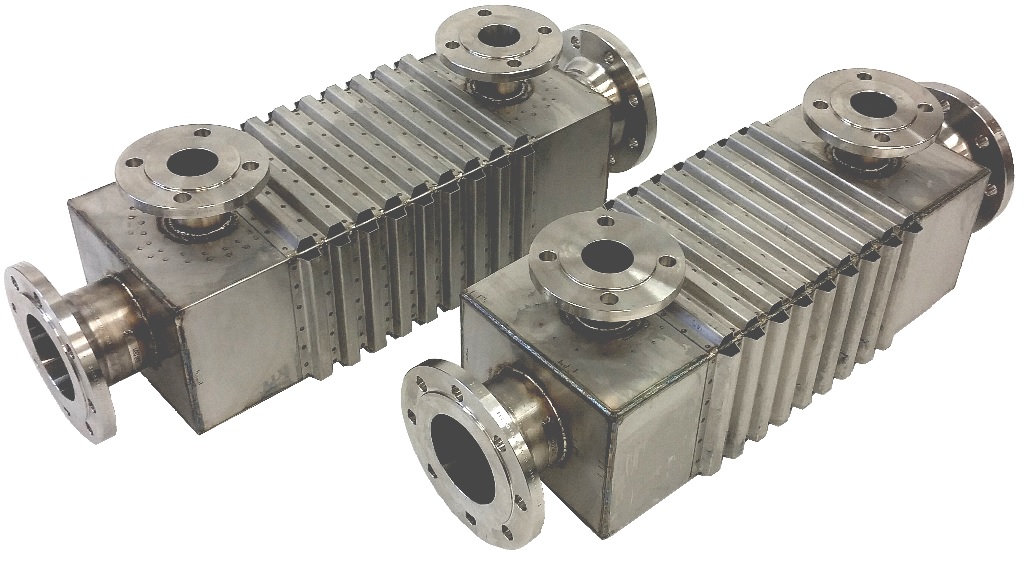

Hilfux was founded to develop a high temperature heat exchanger to serve as a recuperator in microturbine engines for microCHP applications. Hiflux successfully designed and manufactured recuperators in small batches for multiple commercial customers and the technology has logged tens of thousands of hours as part of customer field trials at temperatures up to 800°C.

Innovative design and state of the art modelling tools have been used to create a patented design that has the right combination of strength and compliance required for high temperature operation. An array of pins, laser welded to plates, form the heat transfer path as well as providing structural integrity.

The Hiflux design is made up of a number of identical cells, each cell consisting of two plates joined by pins. The cells are very strong and well suited to withstand the load from a pressurised fluid. The cells are linked together by a novel flexible manifold to accommodate large thermal displacements. Hiflux recuperators are able to operate at higher temperatures than conventional thin foil technology which means microturbine designers can use more efficient hotter thermodynamic cycles, with inherently higher exhaust temperatures. With a counterflow arrangement, a high effectiveness can be achieved. Hiflux customer units typically achieve an effectiveness of approximately 90% and total pressure loss of <5%.

Features

- Reliable operation at turbine exhaust temperatures up to 800°C – 10,000’s of hours service in ongoing customer field trials

- High resistance to creep, oxidation and thermal shock

- Low pressure losses for maximum engine output

- High surface to volume for maximum compactness

- Customers’ exact requirements met with flexible manufacture

- Quality manufacture achieved through automation

- Available in stainless steel, nickel superalloys or a cost-effective mix of materials